Developing the smartness?

Smarting up the development!

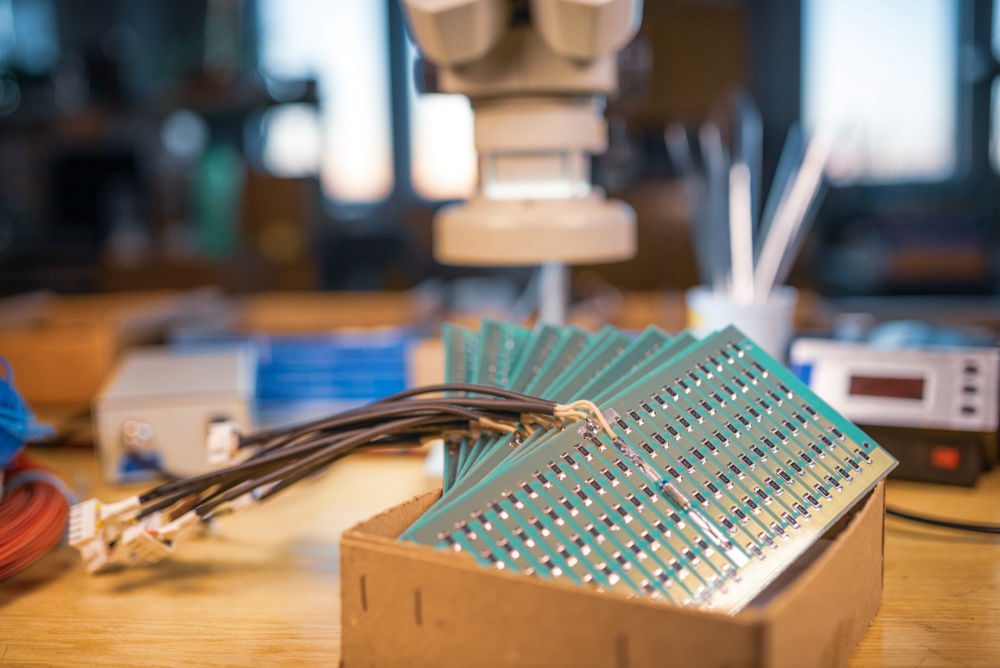

Yes, we know “smarting up” isn’t in the dictionary. That’s the point, it caught your eye. (So will our results). We’re nerds, the useful kind: no hoodies-as-uniform, no tape-mended glasses. When a “coder” is shown, we spare you the pretend-to-be HTML/CSS, and when hardware appears, we don’t stage it with a soldering iron pressed onto a PC mainboard. Promise.